Cost Engineering

True North PLM is here to help you with your cost engineering needs. Whether you need additional support with your day-to-day cost engineering analyses, or optimizing your process with automations to increase efficiencies and eliminate human errors - we are here to help.

Reverse Engineering

With a combination of 3D Scanning and mechanical bucks, we can reverse engineer any part you may need! We have in house scanners, 3D printers, and laser cutters to get a prototype working, and can deliver a quality CAD model and drawing for you to mass-manufacture a part if needed.

Original Part

Prototype

Images Coming Soon

CAD Model

Final Product

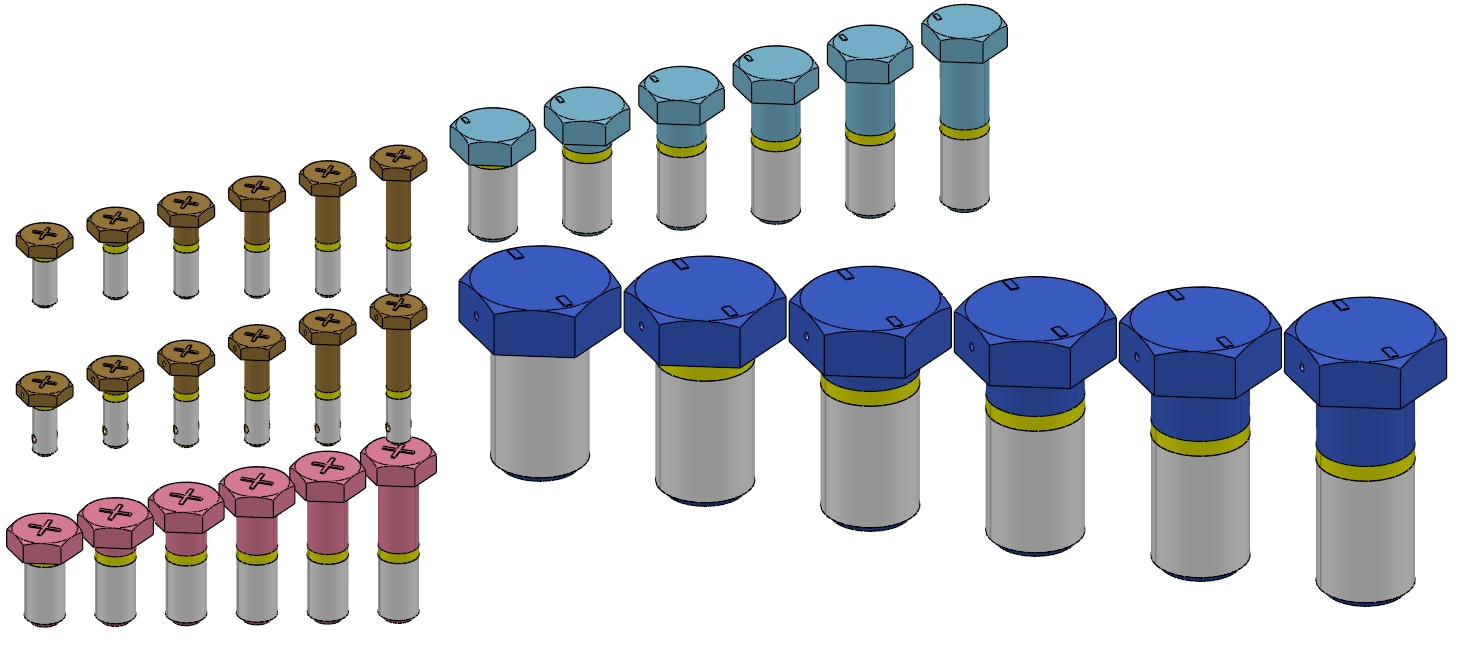

Standard Part Ecosystems

A Boeing 747 is composed of approximately 6 million individual parts, approximately half of which are fasteners (screws, bolts, rivets, washers, nut-plates, etc.)

Fastener-related issues account for approximately 15-25% of all engineering change orders in mechanical assembly industries. This includes automotive, aerospace, and general manufacturing sectors.

Fastener selection and implementation errors contribute to roughly 20% of manufacturing rework costs.

Aerospace manufacturers have reported that fastener-related issues account for up to 30% of assembly errors in complex structures.

The cost multiplier effect: A $0.50 fastener error can cascade into hundreds or thousands of dollars in rework, delays, and engineering time.

Fastener standardization has been shown to reduce engineering changes by 40-60% in companies that have implemented comprehensive fastener libraries and selection guidelines. The standardization of parts can drastically reduce bill-of-material costs.

Consistency is key. Fasteners are the bed rock of any design. In an era where CAD data can be obtained from hundreds, if not thousands, of sources via various industry organizations or supplier web sites, modeling practices, component orientation, 3D accuracy, complexity and adherence to industry standards can vary wildly. This ultimately leads to errors in design, manufacture, quality, service and customer satisfaction.

At True North, our engineers have extensive experience building standard part families across multiple industries. We pride ourselves in our ability to incorporate company / context specific requirements and poke yoke features into the 3D models to drive down engineering time, shorten the review process, drastically reduce manufacturing errors and lead to higher customer satisfaction.

Whether you are looking to refresh your existing fastener dataset, or are starting new programs, True North can create a fastener ecosystem catered specifically to your companies needs.

We can help!